Poly aluminum chloride (PAC), also known as basic aluminum chloride, is an inorganic polymer water treatment agent with the most mature technology and the largest sales volume. It is widely used in the treatment of domestic sewage, industrial wastewater and sludge. It has the advantages of good coagulation efficiency, large flocculation volume, easy storage, low dosage, high efficiency, fast sedimentaation, wide application range and so on.

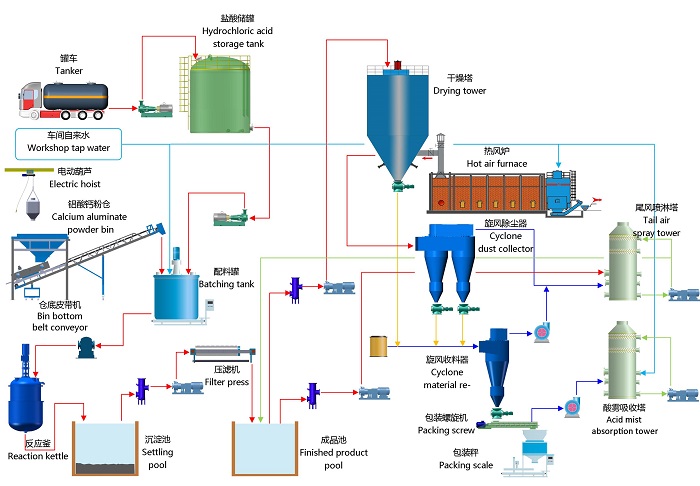

Process introduction:

This process uses calcium aluminate powder and hydrochloric acid as raw materials. Calcium aluminate powder and hydrochloric acid are added into the batching tank in proportion for batching, and the slurry is pumped to the reactor. The materials react in the reactor to produce liquid PAC, and then the filtrate enters the finished product tank after sedimentation and filtration. The filtrate is pumped into the atomization tray at the top of the drying tower, and the droplets flow down with the hot air to dry into powdery PAC. After the finished powder is discharged from the drying tower, it is cooled by the air lift pipe and separated by the cyclone dust collector and falls into the finished product bin for packaging.The dry tail gas and finished product cooling air are dedusted by their respective cyclone dust collectors and then sprayed and washed before being discharged