The wet process of sodium silicate is a production method in which liquid caustic soda and quartz sand are reacted at high temperature and high pressure to obtain sodium silicate. This production method has significant advantages such as low investment, simple process, easy operation, environmental protectionand no waste generation. lt can produce sodium silicate with molar ratio below 2.5.

According to customer needs, we can provide consulting, design, supply, installation, debugging and training services for a complete set of wet process sodium silicate production lines with an output of more than 5000 tons/year.

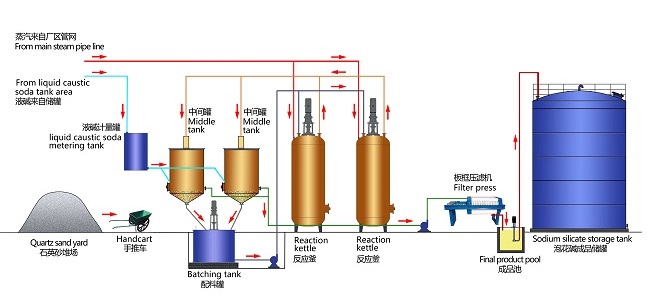

Process description

Quartz sand and liquid caustic soda are mixed evenly in the batching tank, and then put the materials into the reaction kettle and filled with steam. The sodium silicate solution is obtainedafter the reaction of the materials under high temperature and pressure. The solution is pumped to the filter press for filtering to get the clarified liquid product. Then the finished product can be pumped to the finished product tank and sent to the warehouse.